There are different models of issuers. Depending on crop requirements and equipment, there is a different model of transmitter for each installation.

They are differentiated by colors, each giving a concrete and other flow characteristics. They have multiple forms, there are round, wedge, concave, flat, etc.

They can be classified by the flow that provide:

Los podemos clasificar por el caudal que aportan:

- Low flow: 20-40 l / h, used in dense greenhouses plantings of vegetable, nurseries and seed.

- Medium flow rate: 50 to 80 l / h.

- High flow: 100-240 l / h, used in greenhouse horticulture plantations and trees.

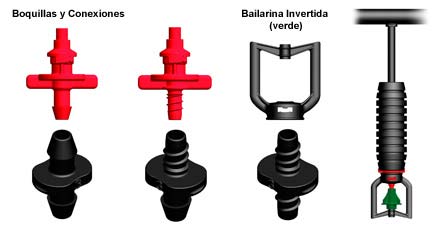

Nozzles:

Generally the most common type of nozzle is the dancer type, as this microsprinklers type are designed in a modular way, with interchangeable parts, enabling multiple combinations to meet the needs of all facilities.

We can also find on the market other types of micro-sprinklers such as microsprinklers impact, propeller, etc.

Installation:

The installation of this microsprinklers can be performed by the following ways:

- Inserted directly into the irrigation pipeline.

- Hanging, connected by microtubes to the irrigation pipeline.

- Installed on stakes in various shapes and sizes that rise on the floor and hold the microsprinkler at a certain height on it.

Microsprinklers elements:

The microsprinklers can be coupled multiple pieces that give characteristics that contribute to the optimization of irrigation.

We could include:

- Arc: Its aim is to prevent dripping and shadow areas, favoring irrigation uniformity.

- Anti nebulizer: Device slows down the rate of jet outlet, producing larger droplets which are less sensitive to drag and wind dispersal.

- Flow regulator: A device which maintains constant the flow rate of microsprinkler, within a certain range of pressures. It is basically a device that brings to microsprinkler feature "self compensating".

How to choose the best microsprinkler?

To choose a microsprinkler must to consider:

- Nozzle type depending on the required flow.

- The operating pressure, which will usually be between 1.5 and 2 bar.

- The separation between microsprinklers, which should match its range.

- The line spacing.

- The installation mode.